Industrial Forming Processes

GiD is currently used for data input and visualisation of results for a wide range of industrial forming processes such as sheet stamping, mould filling, solidification and cooling in casting, powder compaction, forging and rolling among others. GiD allows importing complex CAD geometries on IGES, DXF and other formats and generates the necessary input data for the simulation analysis in a simple and efficient manner.

GiD visualisation features can be customised to display the results of interest foreach problem. Current features include animations of the deformed geometry, stress/strain contour plots and line diagrams, forming limit diagrams, porosity contours, etc.

GiD is ideal to be used in a multi-user environment in universities, research centers and enterprises for development and applications of different numerical simulation programs.

Metal Forming Simulation

Stampack is the metal forming simulation software for many industrial applications such as deep drawing, ironing, stretch-forming, forming of thick sheets, flex-forming, hydro-forming, stretch-bending of profiles, etc.

Cooling Process Of A Foundry Piece

Simulation of the cooling process of a foundry piece using Vulcan solver.

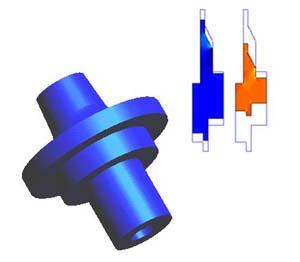

Compaction

Compaction of metal powder components.

(courtesy of AMES SA)

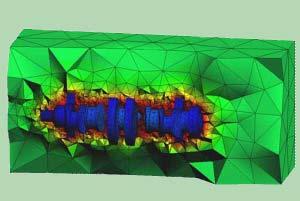

Water Heater

Solidification analysis of a water heater

(courtesy of Roca Radiadores SA)

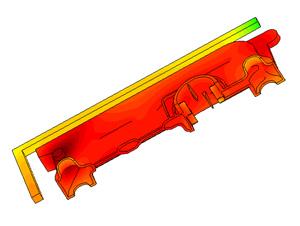

Cooling Analysis

Solidification and cooling analysis of a casted crankshaft. The simulation was run using Vulcan solver.

(courtesy of Renault)

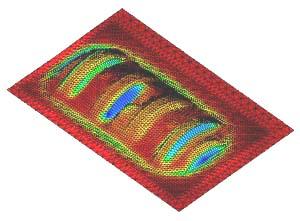

Automotive Part

Sheet stamping analysis of an automotive part. The simulation was run using Stampack solver.

(courtesy of DECAD)